Fit-for-purpose pipe fittings, flanges & couplings for dewatering, slurry & chemical systems. Compatible with poly, HDPE & steel pipelines.

Choosing the right flow meter depends on factors such as fluid type, viscosity, operating pressure, and required accuracy.

Flow meters are essential instruments across a wide range of industries in Australia, including water treatment, fuel management, chemical processing, and food production. They measure the rate or quantity of fluid (liquid or gas) moving through a system, enabling accurate monitoring, process control, and efficiency improvements.

Get expert guidance and precision-engineered solutions for water, fuel, chemicals, and more.

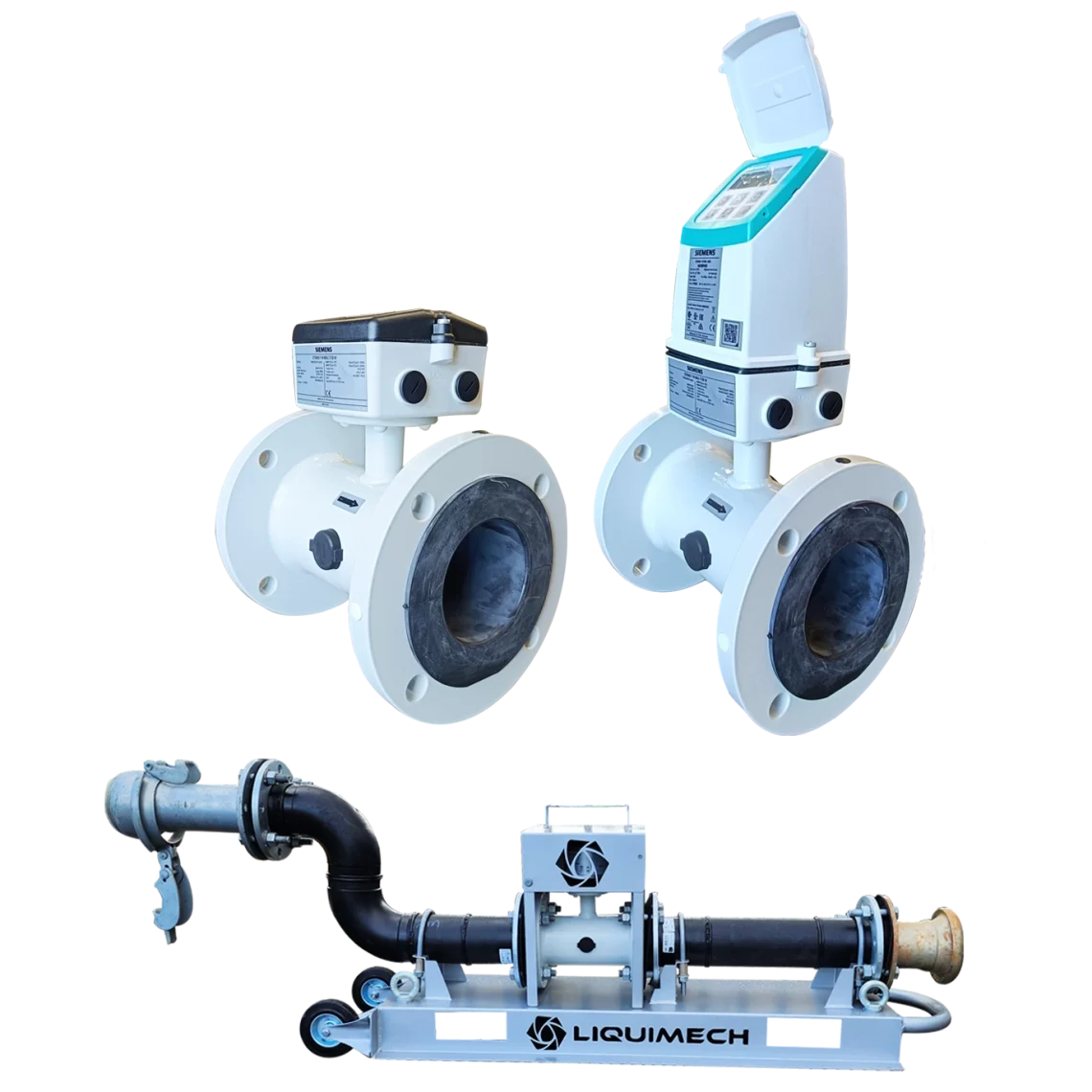

Magnetic flow meters use Faraday’s Law of Electromagnetic Induction. When a conductive liquid passes through a magnetic field, a voltage is induced across electrodes placed in the pipe wall. This voltage is proportional to the flow rate.

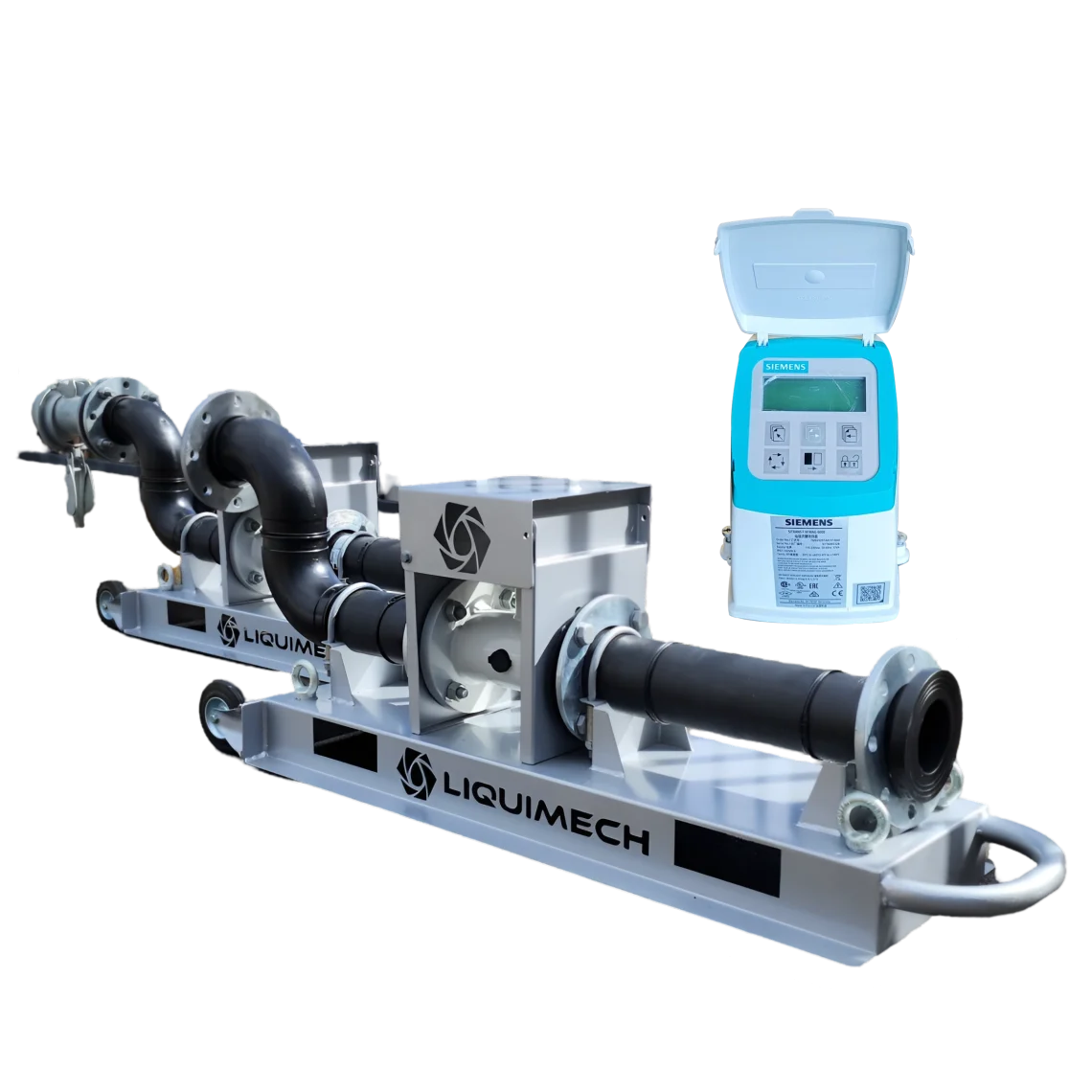

Product Highlight: MAG 6000 Series

Ideal for water and wastewater, mining and mineral processing, and food & beverage applications, efficiently handling conductive, abrasive, and dirty fluids.

Turbine flow meters use a rotor with blades positioned in the fluid stream. As the liquid or gas flows through, the rotor spins. The rotational speed is proportional to the flow rate and is measured by a magnetic or optical sensor.

Clean water and fuels: Works well in low-viscosity, clean fluids.

HVAC systems: Commonly used in chilled or hot water circuits.

Oil and gas: Accurate for refined petroleum products.

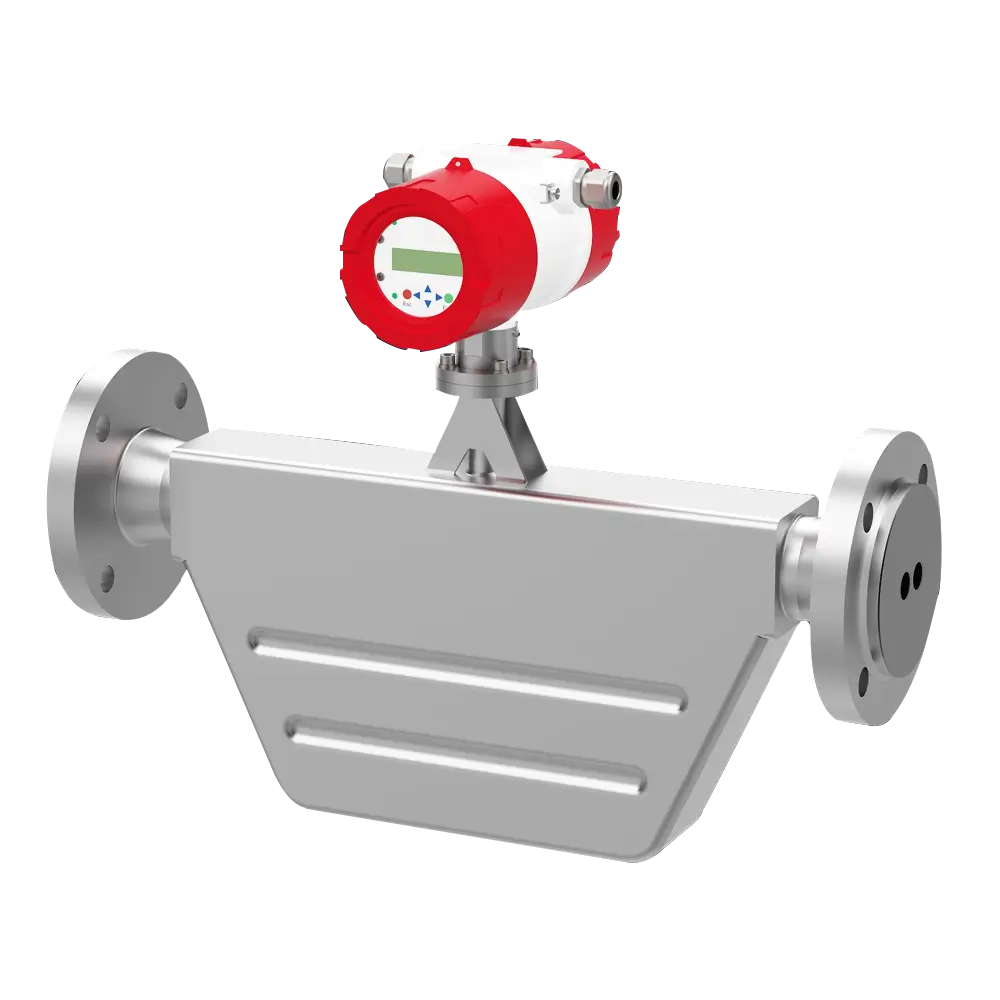

Mass flow meters measure the actual mass of fluid moving through a system, rather than just its volume. The most common type is the Coriolis mass flow meter, which uses oscillating tubes. As fluid passes through, it causes a measurable phase shift in vibration, which correlates to mass flow.

Fuel measurement: Ensures precise fuel usage tracking.

Chemical processing: Ideal for dosing additives where exact mass ratios are critical.

Food and beverage: Used for syrup, milk, and other dense liquids requiring accurate mass monitoring.

Oval gear meters use two interlocking oval-shaped gears that rotate as fluid passes through. Each rotation traps and releases a known volume of fluid, making them positive displacement meters.

Viscous fluids: Lubricants, syrups, oils, and fuels.

Fuel transfer systems: Common in diesel dispensing and bulk fuel monitoring.

Chemical dosing: Handles liquids with varying viscosity and composition.

Ultrasonic meters use sound waves to measure flow. In the transit-time method, ultrasonic pulses are sent with and against the flow direction; the difference in travel time indicates flow velocity. In the Doppler method, frequency shifts in reflected sound waves from particles or bubbles determine flow rate.

Non-invasive measurement: Clamp-on ultrasonic meters allow measurement without cutting pipes.

Large pipelines: Works well in water distribution and oil pipelines.

Temporary or portable flow measurement: Ideal for audits and system testing.

Liquimech offers a wide range of water flow meters for industries across Australia, including impeller flow meters, digital water flow meters, mechanical flow meters, portable flow meters, and differential pressure flow meters. Each meter is engineered for precision, durability, and easy assembly

We specialise in supplying and integrating complete water meter assemblies tailored to your operational needs. Whether monitoring fuel, water, or chemicals, our solutions deliver accuracy, efficiency, and compliance with Australian standards, helping you achieve cost savings, process control, and long-term operational reliability.

| Consideration |

What to Evaluate |

| Fluid type | Conductive, viscous, clean, or dirty; chemical compatibility; gas vs liquid |

| Viscosity & Flow Profile | Laminar vs turbulent flow; high vs low viscosity; effect of temperature on viscosity |

| Flow Rate | Minimum and maximum flow rates; ensure meter sizing matches operational range (20–80% of max capacity recommended) |

| Accuracy Needs | Precision dosing vs general monitoring; linearity; repeatability |

| Temperature & Pressure | Maximum operating temperature and pressure; compatibility with meter materials; effect on seals and electronics |

| Maintenance Requirements | Non-invasive or low-maintenance options |

| Installation Requirements | Orientation (horizontal/vertical), pipe configuration, straight-run requirements, flow conditioning |

| Output / Indication | Analogue, digital, pulse, and power supply requirements. |

Have a custom project? Our team of engineers is ready to design or adapt flow measurement equipment to meet your unique needs. Get tailored advice on the best flow meter for your application and benefit from expert guidance and complete flow management solutions.

Contact Liquimech today to get started.

Industrial flow measurement is critical for ensuring consistent product quality, operational safety, process optimisation, and environmental protection. Every day, industries measure and manage water, natural gas, steam, mineral oil, and chemicals.

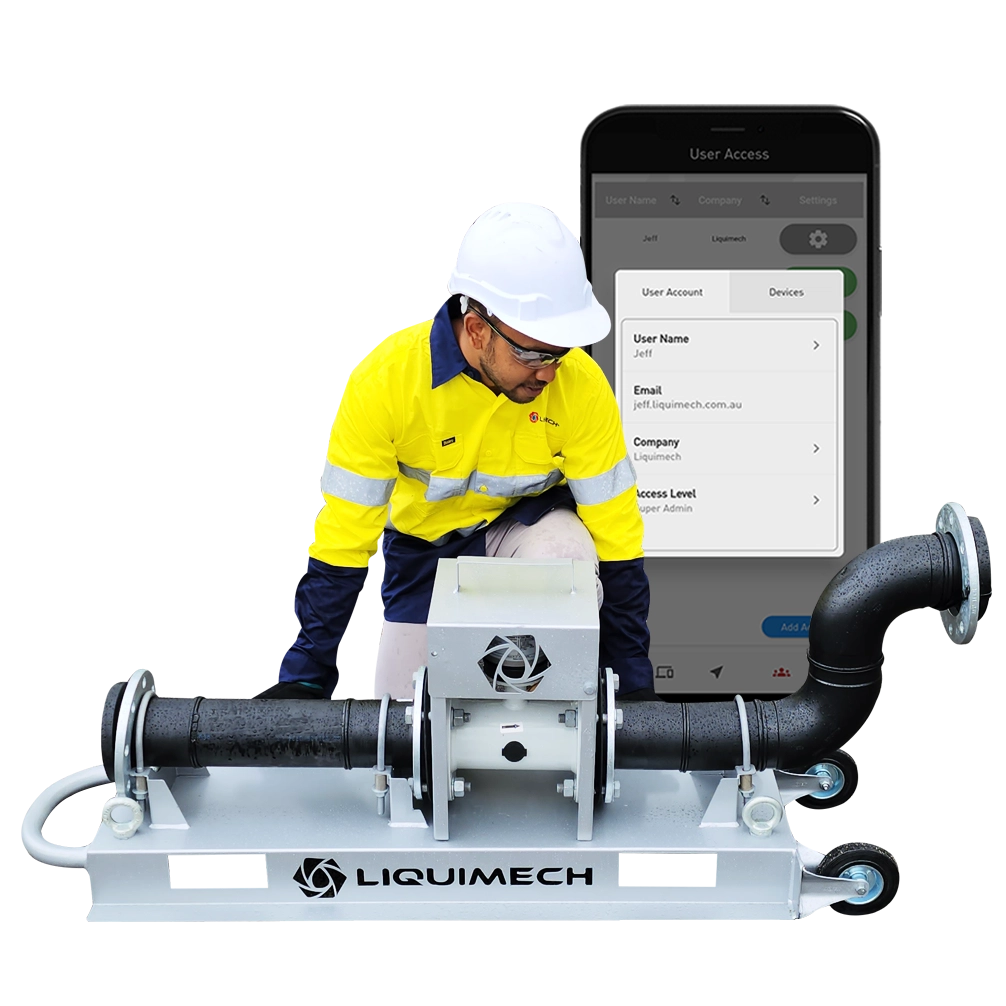

Liquimech offers a comprehensive range of flow measurement technologies tailored to your operational needs. In many areas, it is mandatory to measure how much liquid is pumped from A to B or how much water is discharged or extracted from a particular area. Liquimech boasts a large range of water flow meters, including mechanical water flow meters, electromagnetic water flow meters, portable water flow meters, mass flow meters, differential pressure flow meters, and ultrasonic flow meters. Depending on the site requirements, Liquimech engineers will work with you to provide a fit-for-purpose solution. Liquimech’s unique design approach ensures that each project is analysed on its own specific requirements and regulations to ensure a seamless process from “issue to integration”. Liquimech boasts a team of engineers; including Software, Systems, Mechanical, Automation and Electronics, to ensure any project of any size is exacting to the environment in which it will be used. Liquimech’s flow sensors and flow monitors, monitor flow and flow rates of liquids; including slurries. A flow sensor can be as simple as alerting users if flow is detected, whereas a flow monitor can be coupled with our fully automated systems to cut off supply when a pre-set value is reached. Liquimech’s range of Water Flow Meters is often coupled with our telemetry control systems and alarms to provide complete control and peace of mind.

At Liquimech, our priority is to provide products and systems to make your working life easier, minimising frustrations caused by poorly functioning equipment and unplanned downtime. We supply a wide range of standard products to suit most applications, or we will work with you to create a bespoke solution if required.

When measuring, controlling, or monitoring fluid flow in industrial processes, a flow meter provides the critical data you need to make informed operational decisions. Choosing the right meter ensures accurate measurement, process efficiency, and long-term reliability.

Here are the seven essential considerations when selecting a flow meter:

How Do Flow Meters Help?

Flow meters are essential in every stage of water production and distribution, helping municipalities and industries across Australia achieve accuracy, efficiency, and compliance. From sourcing raw water to final delivery, the right flow meter ensures reliable measurement and control. For proven solutions, a flow meter Australia supplier like Liquimech offers technologies tailored to every application.

Acquire:

The first step in water production is acquiring water from ground or surface sources. Precise flow meters help manage pump performance and downstream treatment efficiently. Technologies such as electromagnetic, clamp-on ultrasonic, open channel, turbine, and differential pressure meters are commonly used at this stage.

Clarify and Filter:

During clarification and filtration, monitoring flow is crucial for the correct distribution of coagulants and polymers. Accurate flow meters also ensure effective backwash cycles for filtration systems. Advanced technologies used here include electromagnetic, clamp-on ultrasonic, turbine, and differential pressure meters.

Treat and Disinfect:

Treatment requires adding exact amounts of disinfectants, pH correction agents, corrosion inhibitors, and fluoride. Reliable flow meter solutions ensure dosing is accurate and compliant with strict safety standards.

Distribute:

Water distribution involves more than just delivery; it requires balancing loads and detecting leaks. Electromagnetic and ultrasonic flow meters provide precise measurement for efficient, leak-free water distribution networks.

Deliver:

Final delivery to homes, businesses, and industrial sites relies on highly accurate flow measurement. Electromagnetic, ultrasonic, and positive displacement flow meters are best suited for this stage, ensuring every drop is accounted for and delivered effectively.

Liquimech offers the best water flow meter solutions in Australia by delivering unmatched precision, reliability, and long-term performance for a wide range of industries and applications across the country. Designed for accurate measurement and process control, our flow meters are trusted in demanding environments where consistency and durability matter most.

Liquimech’s expertise ensures that each water flow meter is tailored to your application, providing reliable, long-lasting performance in even the most demanding conditions in Australia. From industrial facilities to municipal infrastructure and environmental monitoring, our flow meters help organisations across Australia optimise water management, improve operational efficiency, and meet strict compliance standards.

Find The Solution To Your Operational Problem

We have been dealing with Liquimech since they started out, and they have never let us down. With both our companies being Australian owned and operated, our values align perfectly, we pride ourselves in manufacturing high quality Australian Made products. I highly recommend Liquimech and wouldn’t think to go anywhere else, appreciate all you have done and look forward to what is to come!

– From the DomeShelter™ Australia Team

It’s exceeded our expectations. High quality, we don’t need any counter weights and it’s easy to set up. It’s been in operation for 6 months now with no hassles, we’ve got quite a substantial pump driving water to the standpipe and we haven’t any issues. Overall quality & reliability supplied by Liquimech has been very impressive.

Feedback from site is that the standpipe is working well. Thanks for arranging fast delivery!

I’ve been dealing with Liquimech for some time now and can’t speak highly enough of what they do. With top-notch service and products, great lead times, and very competitive pricing, they really cover all the bases. I couldn’t recommend Liquimech highly enough for anyone that wants all three sides of good, fast, and cheap.

As always Ryan Wallis you deliver.

Liquimech Connect offers advanced measurement, monitoring, and control for liquid-based processes, optimising efficiency, performance, and safety.

Automate Your Liquid Management Today!

Our bespoke packaged solutions are custom-designed and extensively tested to handle any challenge.

We go the extra mile to deliver exceptional products, using strict quality standards and rigorous control.

We build lasting, strong customer partnerships through consistent success, reliability, and trust.

Our job extends beyond delivery; we provide dedicated after-sales support to ensure your success and satisfaction.

"*" indicates required fields

We specialise in engineered-for-purpose equipment and customised solutions designed to meet your unique requirements.

1300 954 202

sales@liquimech.com.au